The m. conti has been producing presetters for over 30 years. This experience has allowed to understand the importance of ease of use and ergonomics. In m. conti these important factors are held in great importance when designing presetters. Everything is within reach and easy to handle.

Designed and developed by  and Sistemi in the field of tooling manufacture, the Preset PERFORMANCE are also essential in sharpening centers and production units of furniture or windows, for checking the condition of the tools and their settings before being mounted in the machine. Accuracy represents less waste, less CNC machine downtime and more profit for your business.

and Sistemi in the field of tooling manufacture, the Preset PERFORMANCE are also essential in sharpening centers and production units of furniture or windows, for checking the condition of the tools and their settings before being mounted in the machine. Accuracy represents less waste, less CNC machine downtime and more profit for your business.

TECHNICAL FEATURES

- AXIS Z: Oversize, heavy duty, steel column. Thermically stabilized. SP class precision linear guide and preloaded with recirculating bearings. Linearity of movement is guaranteed by 1 guide with four-row linear recirculating ball bearing with preloaded slides. It is equipped with glass optical scale with micrometric resolution (0,001) and supplied with their inspection certificate

- AXIS X: Stabilized steel plate, ground to a ±2μ planarity. Guides are directly fixed to the steel base of the presetter to guarantee constant geometry alignment. Linearity of movement is guaranteed by 2 parallel guides with four-row linear recirculating ball bearing with preloaded slides. Guides are directly fixed to the steel base of the presetter to guarantee constant geometry alignment. It is equipped with glass optical scale with micrometric resolution (0,001) and supplied with their inspection certificate.

- Interchangeable tool sleeves are made in tempered steel with high precision (internal cone run-out ±2μ). Calibration spheres integrated in the tool sleeve for fast and precise zero setting.

- Pneumatic lock and unlock of both axis movement can be done using only one hand. A single button is located on the handle for a comfortable grip and fast positioning. Perfect balance of the support column allows smooth movement with minimum effort.

- The Performance range is equipped, as a standard, with Interlock System which allows great precision even when measuring very high tools. Just a turn of the knob and the efficient locking mechanism is activated. The system is flexible and can be used with the vast majority of standard pull studs. Tool sleeve rotation brake for the best spindle lock is also a standard feature.

- Precise and readily at hand the micrometric wheels allow anyone to reach any position on the tool with micron precision.

- High performance dust guards maintain the presetter guides and sliders in perfect shape at all times. The presetter can work in difficult conditions.

- Telecentric lenses on the HD main viewing cameras. Field of vision of 7 x 7 mm and 40x enlargement. Tool measuring, with 0,001mm resolution, and inspection is possible in Real View mode is possible.

- LED ring cold light for the frontal illumination of tool surface. Light intensity regulation is possible.

- The vertical 24”, full HD monitor allows an immediate view of all functions. Viewing angle can be set. As an option a 22” touch screen can be installed.

- A height adjustable support tray holds the wireless mouse and keyboard becoming an efficient workstation.

- PC with last generation Windows® operating system with 7 USB ports. Data saved to SSD hard drive.

- A label printer supplied in order to print relevant tool data.

- Within the presetter support frame a big service cabinet has been created. Easy to access it is an easy way to have equipment protected but all within reach.

COMPLETE TOOL SLEEVES RANGE EASILY INTERCHANGEABLE WITHOUT ANY TOOLS

Tool sleeves are a crucial contact point between the tool and the presetter. The tool sleeves are all easily interchangeable without the need for any tools. The integrated reference spheres eliminate the need of master gauges when zeroing the presetter. Switching over from an HSK to an ISO or a CAPTO is a simple procedure which requires only a few seconds. This is why M.CONTI uses a large surface contact area (200 cm2) between flange and tool sleeve. This solution prevents wear and offers higher precision and stability during measurements.

I - TECH SOFTWARE C.V.S. (Conti Vision System) - FULL (DXF software is included)

ALL DATA IN ONE VIEW

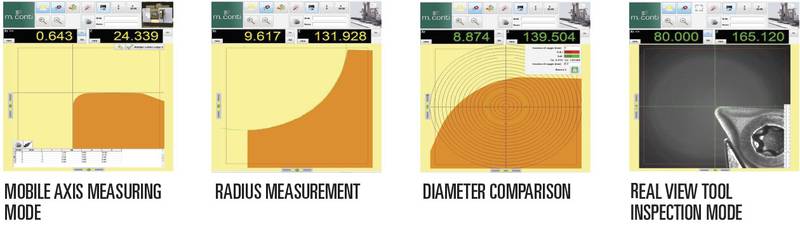

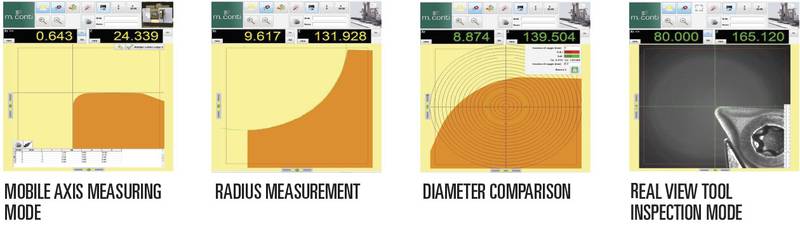

Simple, multi-language and intuitive the CONTI VISION SYSTEM software is easy for everyone. All functions are visualized, with easy to understand icons. It is possible to create up to 200 machine origins and memorize 200 tools for each machine. The tool measuring interface works like a real CAD and any tool measure can be acquired. The new DXF function allows the user to compare tool profiles against imported files or to scan and acquire a tool geometry. The new GHOST function permits to measure the maximum diameter and profile simply rotating the tool. Real view tool inspection mode clear, 40x enlargement, view of tool surface.

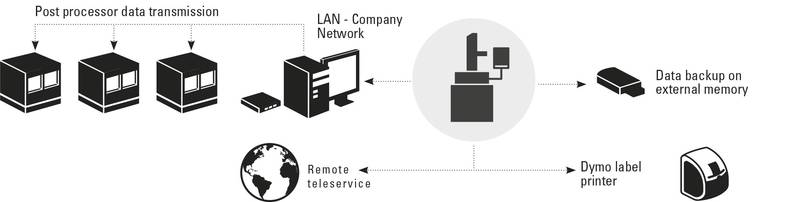

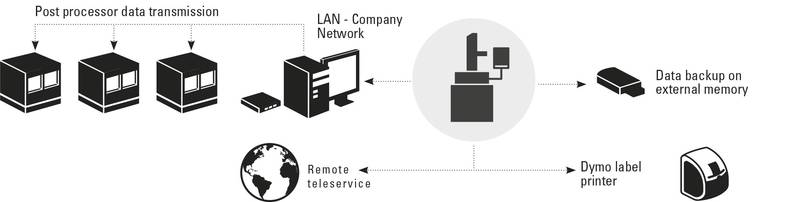

FULL CONNECTIVITY

- Machine tool controls with integrated presetter Post Processo

- Company servers for operations log transfer

- Specific software for Balluff sensor dimensional data transfer

- External memory supports such as USB keys and Hard drives

- Laser printers

- Label printers

OPTION

22" touch screen monitor

DOWNLOAD THE BROCHURE:

![]() and Sistemi in the field of tooling manufacture, the Preset PERFORMANCE are also essential in sharpening centers and production units of furniture or windows, for checking the condition of the tools and their settings before being mounted in the machine. Accuracy represents less waste, less CNC machine downtime and more profit for your business.

and Sistemi in the field of tooling manufacture, the Preset PERFORMANCE are also essential in sharpening centers and production units of furniture or windows, for checking the condition of the tools and their settings before being mounted in the machine. Accuracy represents less waste, less CNC machine downtime and more profit for your business.

View Catalog

View Catalog

Download PDF

Download PDF