Tool presetting for CNC router and moulder machines

Tool presetter: machine set-up

Presetting and measuring machines are essential to minimize fitting times and increase run times of machines and their productivity. It means no downtime of the machine for a higher profit. Not only Presetter for CNC machines but also calipers and gauges for furniture industry are available in our Catalog.

Presetters are used during machine set-up for measuring the tool and have a precise setting of the machines for better productivity and longer tool life.

Tool presetting

During tool presetting, Presetter has the function of cataloguing the information on the dimensions of the tools and transmitting it to the CNC machining center which retrieves it to start the production. It is essential to maintain a high level of certified quality and constant over time. Thanks to a correct preset tool, you will produce the very first part in top quality.

The main advantages of using Presets:

- Greater precision and better machines run times

- Allows you to know with accuracy the geometry of the tools

- Less set-up times with the consequence of better productivity.

Sistemi Klein: our Presetters

There are several different types of Presets. Sistemi Klein is the exclusive distributor of m.conti presetter for the woodworking industry: from the simplest ones with reduced functionality but easy and immediate use, to those equipped with camera and software for the acquisition and direct transmission of the tool data directly to the CNC router, machining centers and moulders.

The entry-level measuring equipment

Our "entry-level" Presetters without the need of electronic connections and without camera, are developed and thought for small spindle moulder machines, through feed moulders and CNC routers. They are used in both wood, metal and glass processing. They are ideal for fast, easy and accurate measurements of the tool and need to be placed directly beside the machine. You can have precise results without any training required.

Discover our entry-level models

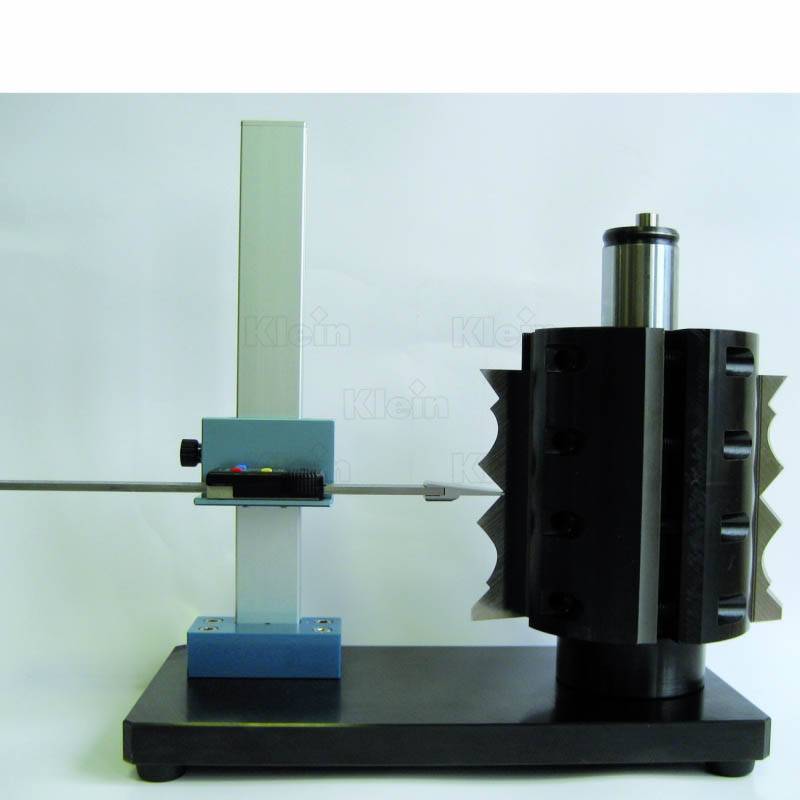

PRESET P322

Preset P322 is the precise equipment for measuring diameter of profiled tools with bore for spindle moulder machines or throughfeed moulders.

Main features:

- Resolution: 0,01 mm

- Arbor height: 230 mm

- Maximum radius: 120 mm

PRESET P368LR

The best measuring instrument for CNC router machines. It can measure tools with diameter up to 250mm and height up to 300mm. It is the perfect entry point to add measurements directly to the CNC router with no errors. It is the best solution for those who owned a CNC router or nesting machines with an affordable pricing. It can also measure profile router bits thanks to a special spheric feeler.

Main features Preset P368LR :

- Store up to 4 machine origins

- Reduce machine set-up time with a steady resolution of 0,01 mm

- Tool sleeves are easy to interchange (ISO, HSK, VDI, arbors)

PRESET P368 XL

Accurate Preset for CNC router and machining centers. It measures radius/diameter and height of the tool in a blink of an eye.

Main features of Preset P368 XL :

- Measure diameter up to 400mm and height up to 300mm

- Easily interchangeable tool sleeves (ISO, HSK, VDI, arbors)

- Sturdy and easy to use

Presetter with camera and advanced features

In addition to the basic tool Presetters, Sistemi Klein also distributes mid- and high-end products designed for tool presetting on CNC machines.

They are all equipped with monitor, camera for checking tool and multilingual Conti Vision System software that allows you to access all functions from a single screen, create up to 50 machine origins and store up to 100 tools for each of them. Micron precision ensures accuracy and repeatability over time.

The Presets are all designed with ergonomics in mind: the monitor is positioned at a useful distance so as not to strain the eye, while the pneumatic movement of the axis reduces the operator's effort.

The materials used are designed to guarantee thermal expansion and to obtain functional design elements with minimal lines.

Discover models with advanced features

PRESET PRIME

The Preset Prime comes complete with CVS SMART software, an HD camera to control geometry and wear of the tool with a 5x5 field of view, a LED illuminator to inspect cutting edge quality and 3 USB ports.

Main features:

- Monitor LCD 19’’

- Maximum measurable diameter is 320 mm

- Manual movement of the axes without effort thanks to the ergonomic handle.

PRESET UNIKO

Preset equipped with a high-resolution HD camera that allows digital magnification up to 40x with a 5x5 field of view, a LED illuminator, 4 USB ports and CVS SMART software.

Main features Preset Uniko :

- Monitor HD 19’’

- Maximum measurable diameter is 400 mm

- Micrometric movement of the axes.

PRESET LEADER PLUS

The Preset Leader Plus guarantees high dimensional accuracy thanks to its thermally balanced steel structure and HD camera with a 7x7 mm field of view, an adjustable LED illuminator, 7 USB ports and easy connection to the company's LAN network to transfer data to the machines (it means no input errors, fewer rejects and no machine downtime).

Main features:

- Monitor Full HD 22’’

- Pneumatic movement and locking of the axis

- Software CVS FULL with possibility of DXF software implementation.

PRESET PERFORMANCE

Ideal for dimensional and status inspection of tools in grinding centers, tool manufacturers, furniture or window and door manufacturers. Preset Performance comes complete with an HD camera with a 7x7 mm field of view, an adjustable LED illuminator, 7 USB ports and CVS FULL software with DXF import-export included.

Main features:

- Monitor Full HD 24’’

- Maximum measurable diameter is 600 mm

- Pneumatic spindle rotation brake for extreme precision.

Italiano

Italiano English

English Français

Français Deutsch

Deutsch Español

Español