Calipers: Measuring Instruments in woodworking industry

We all know that making really good furnitures, as for example tables, closets, beds or chairs requires expertise and professional equipment.

An efficient support in the woodworking industry are the measuring instruments. These ones offer a large scenario of needs, target and budget in order to create high quality products. But, to achieve this goal, it is necessary to consider also one of the most important aspects, that is that every processing level must be followed by a control phase. The control phase can be done with the right measuring instrument made specially for woodworking and panel industry. Moreover, this is absolutely important when the company or the craftsman himself works on behalf of a third party and for this reason it is indispensable to respect the quality standards dictated by the buyer or the big company.

The caliper is a precise and complete measuring instrument

It is very useful in the woodworking industry, because it can measure the panel length or diagonal, the width of the elements to produce or the distance between two or more holes.

It is very useful in the woodworking industry, because it can measure the panel length or diagonal, the width of the elements to produce or the distance between two or more holes.

At the beginning of the productive stage, panels are cut and then measured in order to verify the accuracy of their previous production so that to move on to the next production level, that is the drilling phase. In the drilling phase it is necessary to measure the distance between centres by using the related gauge to verify if there are possible variations of the predetermined measures.

It is possible to choose your own gauge selecting between the large range offered for every production phase.

We can distinguish gauges on the base of their measuring capabilities or their data interpretation:

Gauges for linear measurements suitable for widths and heights or lengths.

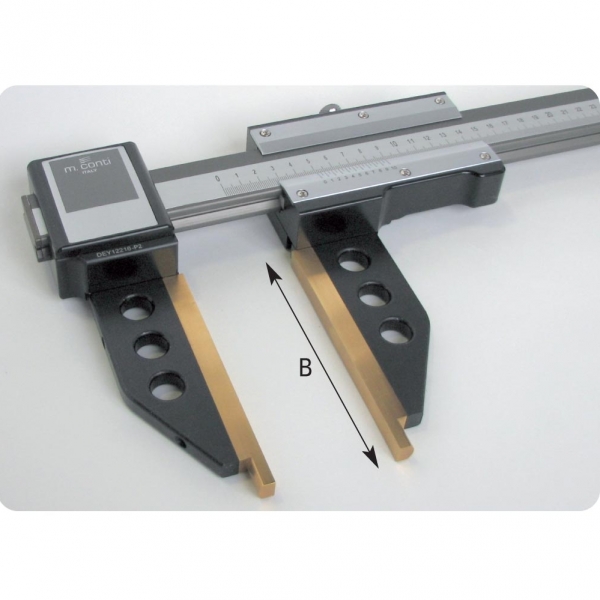

Gauges for linear measurements suitable for widths and heights or lengths.- Gauges for measuring distance between centres suitable for measuring the distance between holes. An essential control in order to create a high-quality product, easy to mount, perfectly linear.

- Gauges with nonius made with a calibrated fixed bar and a moving slider with a graduated scale (nonius). The decimal nonius allows to achieve the tenth of the millimetre.

- Digital gauges that permit an instant and easy reading of measuring with the advantage of modifying the unit of measure from millimeter to inches.

The digital technology bypasses the subjectivity of the operator and speeds up the measuring process.

The importance of measuring during woodworking

Checking by using measuring instruments during each processing phase allows higher productivity. This permits to avoid errors, unexpected events or production interruption. A right control phase allows to modify, or correct, measures directly when working, specially when we are talking about wood, chipboards, aluminium bars or sheets and all other materials that need an accurate measure to maintain a high-quality level.

Checking by using measuring instruments during each processing phase allows higher productivity. This permits to avoid errors, unexpected events or production interruption. A right control phase allows to modify, or correct, measures directly when working, specially when we are talking about wood, chipboards, aluminium bars or sheets and all other materials that need an accurate measure to maintain a high-quality level.

Sistemi Klein®

SISTEMI distributes all over the world the wide range of measuring instruments produced by M.Conti for woodworking industry, aluminum, glass and advanced materials. A plus oriented towards large and small-scale industries which require always a high-quality product, able to give a major competitive impulse to their own business. A unique specialization in the market of woodworking technologies. A specialization that improves every year thanks to many years of research and collaboration between Sistemi and M.Conti.

Italiano

Italiano English

English Français

Français Deutsch

Deutsch Español

Español